Resist Flow Monitoring System

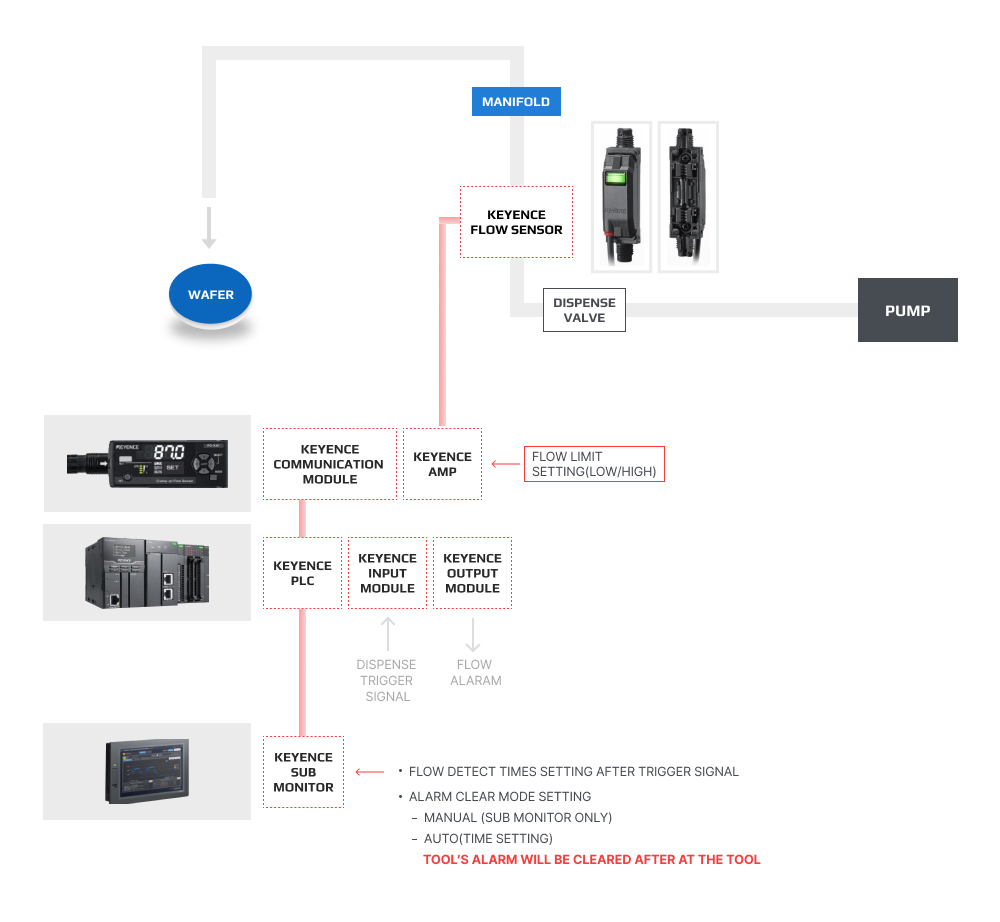

PR dispense monitoring is the key factor for maintaining the coating quality. Apple T offers resist flow monitoring system with reliable Keyence sensor to monitor resist dispense regardless of its viscosity or dispense amount. The clamp on type sensor (no cut) can offer accurate measuring of each dispense, and alert the user for any abnormal dispense during the operation.

Clamp-On Micro Flow Sensor

- No Viscosity Limits allowing Low to High Viscosity Resist Monitoring

- Easy Application without line cutting à No Impact on Process

- Easy Setting & Calibration

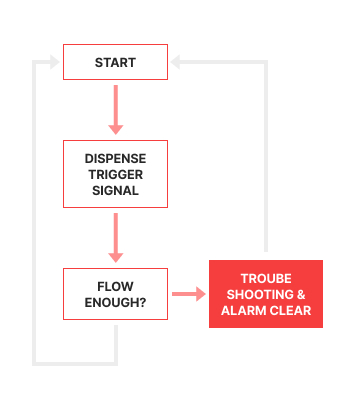

Interlock system

- Monitoring Dispense condition and Alert for abnormal dispense flow

- Protect Non-Coated wafers from being undetected

- Cost saving on rework from detection at the early stage

- Save wafers from scrap & rework

Display dispense volume log

- Record the Log data for further analysis

No maintenance Required

PR FLOW SENSOR

- Clamp-On Micro Flow Sensor

- No line cutting à No Impact on Process

- No Viscosity Limits allowing Low to High Viscosity Resist Monitoring

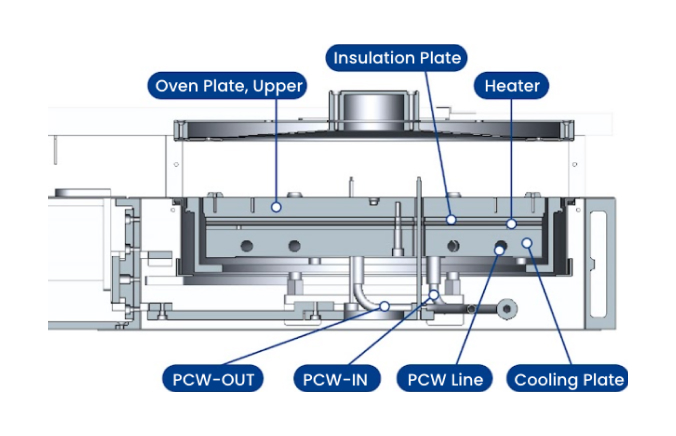

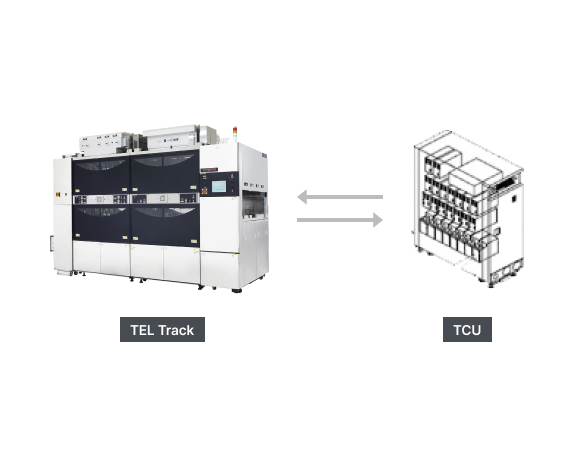

LHP Colling System

H / W Spec

- iUse original LHP plate + Additional cooling plate

- iTemp. uniformity no change

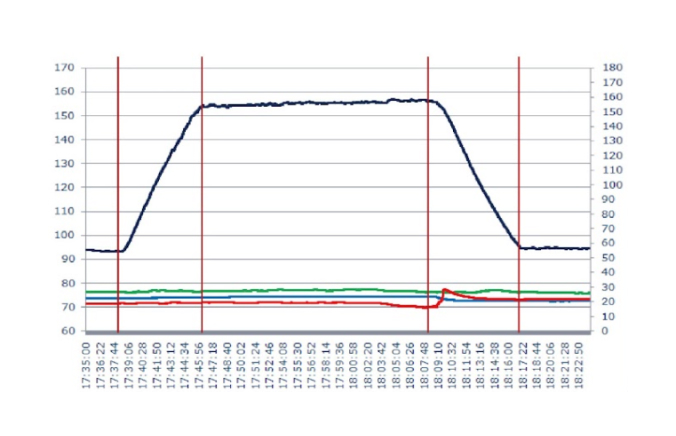

Cooling down performance

- 150C to 90C will be take within 10min

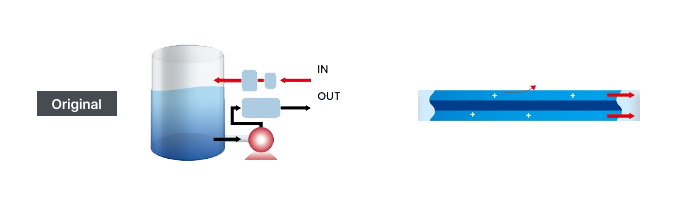

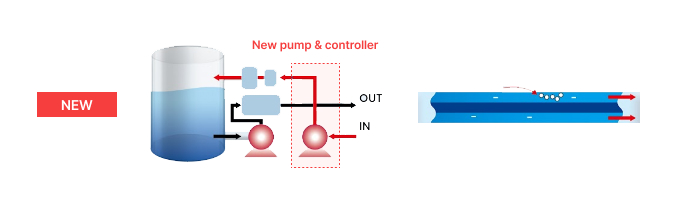

Water leakage protection system

Feature

- No water dripping on the nozzle with negative water pressure

- Easy to detect the leakage of Temp Controlled Water line

- Application: MKS, ACTS & ACT12

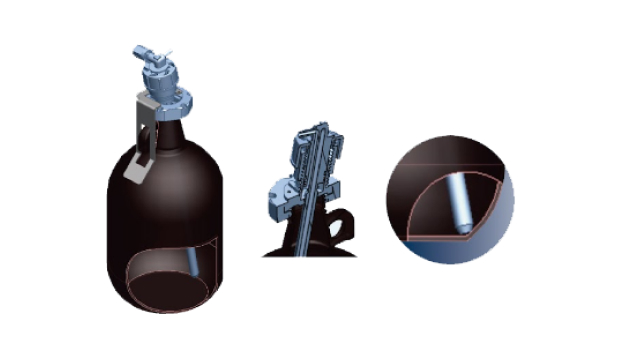

New PR bottle cap

Features of the structure

- Using lockup cap to lock the Bottle - Keep ping the tube in specific position by using Tube Position Adjustment Panel

- By turning the Tube Adjusting Cap, the tip of the tube will reach the lowest point of thebottle

- The tube at the lowest point of the bottle will allow to use up most of the PR. (About 2.0cc of PR residual amount from the test by using the new bottle cap)

New PR bottle cap

- Minimize the unused PR being wasted during PR bottle exchange

- Able to keep the same condition from the repetition of the Bottle change

- Easy application to the current Track tools without extra modification

Auto back up system for #2,3,4 Controller

Mirror System

Mirror System Solid State Drive

Solid State Drive Act #3 Controller

Act #3 Controller

Features of the structure

- The Mirroring System for the #2,3,4 Main Controller of TEL Track.

- No auto Mirroring Funtion/Feature in the OEM Main Controller.

- Allow to save data real time and instant swap of the SSD.

- Reducing the size of the SSD to minmize the space used on the controller.

- Use of 3ea SSD for Master, Mirroring, Slave that allows real time Mirroring & Back Up.